We independently evaluate all recommended products and services. Any products or services put forward appear in no particular order. If you click on links we provide, we may receive compensation.

“Tactical folders” sometimes get a bad rap, for trying to be too tough in a situation they’ll never find their true calling. But, when looking at Emerson Knives, there is a difference. Ernest Emerson has been in close contact with military personnel and law enforcement for decades. He is an instructor in hand-to-hand combat, owns and operates his own training facility in Los Angeles, CA (Black Shamrock Combat Academy Gym), and he makes knives. Really tough, combat oriented knives.

Key Specs: Emerson A-100

The Blade

As much as the blade of the A100 looks plain and simple, maybe even boring, there’s more to it than what meets the eye. 154CM is honestly a bit antiquated in 2020, but it’s still relevant for folding knives. It’s a steel that had a good reputation in its time, and is still well rounded and perfectly useable in today’s market. Without getting too long in the tooth, we’ll just say that there are other “hard use” knife makers still using this steel today, and they charge a much higher price than Emerson. It’s a steel that has great toughness, corrosion resistance, and isn’t too difficult to sharpen. It doesn’t hold an edge as well as many newer steels, but it works fine as a daily user for utility type work, without fear of chipping or breaking the steel.

One attribute of Emerson Knives that just about every model they produce, is a chisel ground edge. It’s a true old school thing to do. Ernie says it’s because he makes knives to be used as tools, and amongst the oldest tools we know of, are chisels. Some of his knives have a true chisel grind, meaning one side of the blade is completely flat all the way to the edge. But some other models, which the A100 falls into the category of, is a “V grind”, with a chisel edge. This means the blade grind is the same on both sides of the knife, but the edge is only sharpened on one side. Check out the pictures for a visual representation of this design.

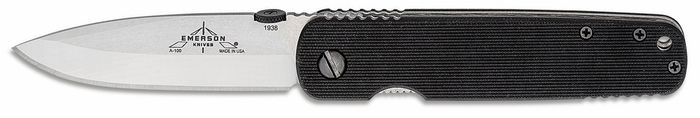

Coming in at 3.6”, and branded with the Emerson logo and text, the satin blade on the A100 is one to be reckoned with. It’s tough, and built for work. Dubbed as a drop point, it has a tip that is centered on the blade. Actually, the tip of the blade, down to the center of the handle butt, is symmetrical. The grind on the blade is more or less a saber grind, with the chisel edge. This is to give the edge strength, when doing light prying, or twisting the knife after it’s been pushed into a material. The A100 blade also has a nice finish to it; the flats of the blade are stonewashed, and the beveled portion are satin. It’s a nice contrast, and gives the blade a simple, clean look.

Deployment and Lockup

The “Emerson Opener” has been trademarked by Emerson Knives, and has been used on many Spyderco knives with homage to Emerson. It’s a secondary deployment method to a traditional opening method, which is essentially a hook cut into the base of the blade, that snags on the pocket upon pulling the knife out, simultaneously deploying the blade. And almost all of Emerson’s knives have this deployment method. But not the A100. This model has a simple thumb disk mounted to the spine of the blade. It really works well, and also gives your thumb somewhere to rest when using the knife.

The action of the A100 is not one to write home about. Nylatron washers are not meant to compete with the frictionless action of ceramic bearings, or even phosphor bronze washers. But, they are supposed to be tough, resist deformation, and be more resistant to corrosion and debris than other options. The knife can still be flicked open quickly, and with a little tuning of the pivot, it’s smooth enough that I didn’t have any complaints.

The lockup on this knife rivals some of the best. There is no blade play in any direction. Liner locks are great, if implemented well, but can be dangerous in the hands of manufacturers with low tolerances. This liner lock definitely has the feel of a higher end knife as far as solidity of lockup is concerned. But there’s a caveat; significant lock stick. This is apparently an inherent design byproduct of this particular knife. All my research on the topic comes back with the same result.

It’s a lock that just has some stick to it. For me personally, it drives me crazy. I have a theory that part of this lock stick is due to the liner being titanium. A softer metal (titanium), mating up with a harder material (hardened steel), typically causes this stick to occur. Some argue in defense of this lock stick, saying that it just gives a more solid lockup. That may be true, but in knives in the $200 price range (and the A100 is close, at about $180), I’d prefer the lock to disengage normally.

Features, Fit and Finish

One of my favorite features of the Emerson lineup is their choice in hardware. When I see Phillips and flathead screws throughout the entirety of the knife, I’m happy. I’ll admit that my normal knife maintenance kit only houses torx drivers for most other manufacturers’ standards, but I like knowing that if I’m out on a job or at a workbench, I know I can find what I need to break down my tool if necessary.

And speaking of breaking down the knife, another feature of the A100 is the previously mentioned titanium liners. Titanium isn’t some magic metal that fixes all the world’s problems, but it is lighter than steel, and generally won’t corrode hardly at all. With the knife disassembled, we get an inside look at the fit and finish of this rough and tough folder. Grind lines are left rough on the liners, which I personally think has a cool look to it. But the edges are not smooth, the drilled holes for screws are not chamfered, and the liners and hardware have a “just off the shop table” feel to them. Kind of a gritty feel, just like after doing some grinding on a bench grinder.

The fitment of all the parts of the A100 is great. All the screws sit nice and flush, they thread back together well, there’s absolutely no wiggle or play in any direction, and all the parts line up well when I reassembled the knife. The liners sit flush to the G10 handle scales. The pivot has a D-shape cutout in the liner to prevent it from spinning infinitely when disassembling. The jimping lines meet up very well between the liners and the G10 scales. There is jimping in a few places on this burly little folder, on the blade spine, back of the handle, front of the handle at the butt, and on the liner at the lock cutout. That sounds like a lot, and I venture to say it kind of is. But it doesn’t feel as aggressive as something like the Spyderco Manix 2, the most “over-jimped” knife I’ve personally ever had.

The A100 is not ambidextrous, though. The opening method is, with the thumb disk protruding from both sides of the blade spine. But, the pocket clip cannot be reoriented, and the lock cutout is really only right-hand friendly. Not a deal breaker for most, but possibly a deal breaker for lefties.

Field Test

I enjoyed using this knife. But I didn’t enjoy carrying it. In use, the handle is neutral, the blade cuts well, holds up to harder use, and looks good while doing it. But it carries like a stick wrapped in sandpaper.

When considering running my usual 3 part cut test with my folders, I didn’t expect great performance from the A100. It’s a narrow blade, chisel ground, old school steel, and ground like a mini pry bar. But I was wrong. I was pleasantly surprised to use this tool. In the apple cut test, I did have some minor cracking on the slices, but honestly not much more than with something like the Sebenza. I really thought this blade was going to just turn the apple slices into confetti, but it’s actually not bad at all.

Moving on to tearing down a few medium sized cardboard boxes, I had the same level of surprise that came with the apple cutting. The blade bites nicely into the material, and didn’t give me nearly as much resistance in cutting than I expected. I’d compare the cutting feel of the A100 similarly to the Spyderco PM2, partly because of the similar feel in performance, and also because many knife users will have a reference with a very common knife. Punching through the cardboard with the tip was also very easy, which was a little less of a surprise, as the tip is well done on this blade. The spine had a nice small swedge to bring the tip of the knife to a somewhat acute point. Very well done, Mr. Emerson.

And the 2×4 wood shaving test. This is where I put some punishment on this knife. I didn’t do any chopping, as folders are too light to really chunk out any material. But I allowed the blade to naturally bite deep into the wood, much deeper than any other knife I’ve tested. I measured about 1/2” deep slice, and twisted the blade hard. This popped the thick wood slices away just like I wanted it to. I did this over and over until I felt like I had some confidence that it just wouldn’t stop. This knife is made to do these harder use types tasks, and it shows. I also stabbed the wood and pried using the tip for a little while. Made a nice deep hole in the wood. This was the only test I did where I could see visible edge damage, but only at the tip. It never broke off any material, but it rounded the tip over just a little.

I went ahead and sharpened the knife at this point, since I beat it up pretty well. This was a little bit of a challenge for me personally, as I’ve never attempted a chisel edge knife before. With only one sharpened side, it should be twice as easy, right? Well, sort of. Sharpened at about 21° per side from the factory, I was able to follow the factory bevels throughout my sharpening progression. I had worked up a decent burr on the unsharpened side of the blade. Removing that burr was the difficult part, because I didn’t want to have an edge bevel on that side of the blade. I was able to use a higher angle on the stones on the chisel side, and work the burr back and forth a few times. Then stropping as usual, I came up with a nice clean edge that was better than the factory sharpening.

Carrying the A100 is not for the feint of heart. It’s not overly heavy, at 4.9oz, but it does have some heft to it. The pocket clip placement is low on the handle, leaving a good amount sticking out of the pocket. This makes sense for this knife’s intended use, but for a casual EDC folder, it’s a little extreme. And the G10 texturing is literally like sandpaper. I can’t really overstate how grippy it is. Which is great for wet environments, or if you happen to be someone with enough hand to hand combat training to rely on your folder for defense. But again, for edc use, it’s a literal pocket destroyer.

Alternatives

All these knives available at BladeHQ.

The Benchmade 940 is arguably a very comparable knife to the A100. Its similarly priced at ~$190 for the aluminum handled model, or ~$175 for the G10 model. The blade lengths are within 1/4” of each other’s. S30V on the 940’s blade steel composition vs the A100’s 154CM, while not exactly the same, have some close characteristics. The 940 is between 2.6-2.9 oz, basically about half the weight of the A100, and runs on phosphor bronze washers rather than the Nylatron that Emerson utilizes. Of course the Axis lock found on Benchmade knives is much more fidget friendly, but both knives are considered the staple of each company’s lineups.

Emerson’s CQC-7 is another viable option for those looking for a knife in this category. It’s another one of the company’s early designs, and is quite similar to the A100. Its the same price, but comes in either a tanto or spear point, whereas the A100 is spear point only. The CQC-7 also has the signature Emerson wave opening feature to its blade deployment. The blade is a bit shorter, at 3.3” vs the A100’s 3.6”, and is probably geared even further toward the hard use spectrum of knife use. It’s also made in the USA, just like all Emerson knives; an important buying factor for some users.

Conclusion

The A100 is a knife that, to me, screams old school. Most folders of late have thinner blade stock, lend themselves to being better “slicers”, have more smooth, free dropping action, and more modern steels. This knife has none of these attributes. That’s absolutely not a bad thing. It’s kind of fun and refreshing to use a knife that feels like it came to the future from 30 years ago, but can still unquestionably hold its own in any day to day cutting task. And knowing it’s something that comes from an American made small business, from a true old school knife maker, a family run business with real world tactical heritage gives the knife a feel of history and significance in the knife world. But don’t expect it to jump through the hoops that many modern folders aim to perform.

- Tough, solid and simple; it’ll get any job done with confidence.

- Extremely rough G10 texture, antiquated steel, carries high out of pocket.

Emerson A-100

Quality/Performance - 73%

Value for Money - 66%

70%

The A-100 is an old school folder - tough, simple and effective but not without some shortcomings.