We independently evaluate all recommended products and services. Any products or services put forward appear in no particular order. If you click on links we provide, we may receive compensation.

Andrew Demko is a knife maker, designer, and innovator. He has collaborated with Cold Steel on many of their knives, including the AD10, AD15, AD20, 4Max, and many others. And, one of Cold Steel’s claim to fame, the Tri-ad lock, was also brought to their lineup by Mr. Demko. This guy makes heavy, hard use, tough knives, and Cold Steel is the perfect company to bring those designs and innovations to the production level, allowing a higher number of units to be made for the masses.

And the AD15 is definitely one of the more unique knives in this niche knife sector, both asthetically and functionally. Utilizing the Demko designed scorpion lock, It’s another “hard use” design, that is magnified in strength by the grip of the user. This is one heavy, tough, lovable knife, that’s just begging to be used.

Key Specs: Cold Steel AD15

The Blade

3.6” of S35VN steel doesn’t sound all that unusual. The legendary Sebenza shares this exact statistic, and while the Sebenza can absolutely handle some heavier knife tasks, it doesn’t shout hard use from the hilltops. But when the stock thickness is bumped up to 0.15”, and the grind is left more stout with a high saber profile, the stats start to imply something more brawny. Pair that with a stock thickness that’s carried out almost all the way to the tip, a nice swedge carved into the spine, and massive thumb studs, and the result is an AD15 blade.

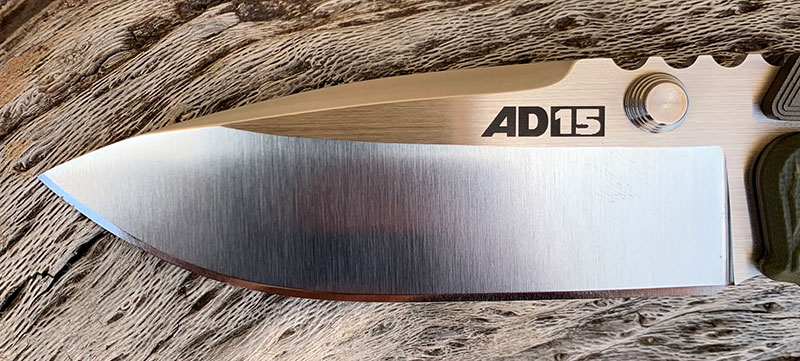

Synonymous with Cold Steel’s loud and proud branding, is the “Cold Steel” branding on one side of the blade, along with “Taiwan” and “S35VN”. And the presentation side of the blade loudly reads “AD15”, in large, bold font, just the way Lynn Thompson (Cold Steel’s president) would have it. Along side the laser etched billboarding, are grind lines that are opposing on the primary and saber grinds of the blade. It gives a dynamic look to the blade profile, while keeping it simple at the same time.

The blade shape is a very simple drop point. It has a very similar look to the Benchmade Bugout, which I consider to be one of the best blades on a folder to date. And the AD-15 cuts really well, and lends itself to actual use with pleasure. We’ll get deeper into performance later on, but the blade shape is absolutely great on this piece, and it looks great, too.

Deployment / Lockup

This is one polarizing knife, both in terms of looks, and in deployment and lockup. With the Demko designed Scorpion lock, the blade is pushed out from its lock position with the large thumb studs, and the back of the handle begins to move away from the front scale of the handle. The lock bar is, in fact, the back portion of the handle. As the blade is moving from its closed position to locked open, the gap between the lock bar and stationary portion of the handle increases, then decreases again to allow the blade to seat.

This explanation should help to understand how the lock bar moves, but feeling it in hand is quite different than anything else. It’s absolutely not bad, but there is a bit of a learning curve. Because of the necessary movement in the lock bar, the user’s hand can’t be pressing forward on that lock bar, or the blade cant open. It all sounds much more complicated than it really is, but to put a new locking mechanism into words can get long winded.

Once you’ve mastered the mechanics of the Scorpion lock, you can appreciate the knife in its opened position, with the lock engaged, and allow yourself to get a feel in hand akin to a fixed blade. There are very few knives I’ve handled and tested that boast the same rigidity and solidity in lockup presented on the AD-15. I was not able to find any perceivable blade play in any direction. And the sound this knife makes when it locks open is truly unique as well, with the aluminum lock bar engaging with the hardened steel blade. There is a stop pin placed in the lock bar for the blade to find its final destination in locking open, which also seats into a notch cut into the blade. What a great design.

And, unlocking the knife gets its own section here, too. A two-handed unlocking sequence may be required for the less mechanically inclined knife lovers, at least until you’ve become familiar with this ingenious lock. But, once you’ve tinkered with unlocking the blade, which has various possible methods in hand placement, you may realize how easy it is to fidget with this hefty brute. But I implore caution here, as with any knife, but this blade is heavy. Watch those digits when flinging the blade home; it’ll remind you in the least pleasant way to keep your fingers out of that freight-train blade path.

Once the blade is back in the closed position, a stud on both sides of the blade dictate where the blade position will sit. At first glance, these nubs may look more like blade stops for locking the blade open, but on the contrary, they’re to help stop the blade from over-closing. Couple these blade stops with the spring assisted lock bar, and the blade keeps itself tucked away, ready for another deployment.

Features, Fit and Finish

The Cold Steel variant of the AD15 boasts G10 handle scales. Some of the custom variants and AD15-MG (MG representing machine ground, while the customs are hand ground) utilize G10 as well, but have various options such as full titanium, micarta, and many color options. The G10 on the Cold Steel variant has a patterned texture cut into the scales. It is just about as aggressive a texture you would ever want on a folder, and many would argue it’s too aggressive. The field test portion of our review will give more input on use of this handle, but for brevity here, let’s just say it’ll stay put in your hand and pocket.

Another feature worth going over on the AD15 is the construction. When disassembling a folder, I feel that I get a much better sense of the machining, fit and finish, and overall design implementation. And the Cold Steel AD15 is quite well done for a production variant of a custom knife. The screws are machined well, and thread together nicely. I really enjoy the rare occasion that complete disassembly (minus the pocket clip) of a knife is done with one single tool, in this instance, a Torx T10 driver is all that’s needed.

Removing these two screws allows the G10 scale and stainless liner under it to be removed. From there, pulling the lock bar back allows the blade to be removed, revealing nearly all serviceable parts of the knife. There is one last option to further disassemble, which is the lock bar and spring that give it constant tension, but that small spring doesn’t typically need to be removed. Sliding the blade out of the remaining scale presents a “D” shaped pivot, which is nice because it prevents the pivot from free spinning when either adjusting the pivot or disassembling the knife.

One oddity found under the hood, is the phosphor bronze washers surrounded by a secondary Teflon washer. At first glance, I didn’t see the paper thin Teflon washer and folded it over just a tad. Didn’t seem to affect anything upon reassembly, but it was one noteworthy aspect I felt necessary to add in here. Otherwise, reversing the procedure proved simple, and the knife was clean and reassembled in minutes.

One design aspect of the AD15 that I don’t hear much about is the exposed blade tang. When the knife is in the closed position, the base of the blade is sitting proud of the handle scales. Quite proud. It’s not unsightly, per se, but it is a mental worry to me. I try and never drop my knives, and I’ve been lucky to not do so in any significant way (yet). But, if the AD15 happened to be dropped on its exposed blade tang, there’s a strong possibility that the deployment of the knife could be hindered, if not destroyed.

With the tang damaged, the blade would potentially get caught on the stop pin as is its being rolled open, causing it to stop and be only opened partially. In an urgent or emergency situation, the lock bar could be pulled back manually to allow the blade to open all the way, and the knife would be useable and safe. But this is an aspect of the design that could be a problem spot for those more accident prone users.

The fit and finish on this knife is worthy of a slightly higher price than its being sold for. I’ve had many knives in the ~$200 price range that felt much less substantial that this. I’ll admit to not having the opportunity to handle the custom AD15 variant, but I’ve been told by a few other fellow knife enthusiasts that the custom is hard to justify after handling the Cold Steel. They’re within 10-20% the quality of one another, but the custom is closer to $500. That’s quite a price hike for some (arguably) slightly higher quality components. There are aspects that could use refining, such as the overly aggressive handle scales, thumb studs not being chamfered as smoothly, and the jimping feeling forgotten on the buffing wheel, but otherwise, it’s a very well put together piece.

Field Test

As much as I enjoy handling a new knife, I like putting it to use even more. And the Cold Steel AD15 was one of the most enjoyable knives I’ve ever used. The ergonomics are really made to be used. So often, I feel like the jimping on the spine of the blade of so many knives is too cramped to use comfortably. The AD15 allows you to hold the knife in the well positioned handle grooves, and lay your thumb on the jimping in the most natural spot. Again, the jimping could use a little smoothing off for a little more comfort, but it’s not terrible. In and out of the pocket is another lackluster aspect of this knife, but it’s not meant to be a smooth, slick, easy to carry EDC knife. I didn’t have a problem carrying it every day, in addition to my daily 2 pound small tool belt, 2 cell phones, 2 sets of keys, a flashlight, and a wallet, but for many users I understand it may be overkill. It is a 6.5 oz knife after all.

I did use some standard cutting mediums, to test blade geometry, real world use ergonomics (rather than desktop review ergonomics), and overall build quality. I grabbed an apple from the fridge, sliced it up, and looked at the results. With a blade stock this thick, I didn’t expect kitchen knife quality cutting, but it wasn’t terrible. The slices were minimally cracked, and were almost edible by my in house food critics, my 7 and 8 year old. But, with cracks like this, our resident Bull Terrier got the “disgusting” cracked slices.

Slicing up some cardboard wasn’t as pleasurable as with a nice thinly ground blade. I give a nod to my Gayle Bradley 1 in many blade geometry tests, and it is my personal gold standard for cutting performance. The AD15 is fine for cutting open an Amazon box, or tearing down a spare large piece of cardboard for the trash. But I wouldn’t go processing the remnants of Christmas Day with this knife. I had the blade actually warm up a significant amount slicing up about 5 large boxes. Not a big deal, it happens with some thicker blades knives, but it’s a good indicator of how hard the blade is being pushed to part the material.

And the 2×4. I wish I had taken a video for YouTube with this test. First, I shaved down some small feather sticks. Easy enough, and the ergos proved to be great. Then, I dug a little deeper, and shaved off some large chunks. The blade started to get stuck, so I went ahead and started to twist those pieces out. I did 3 of 4 of these, and checked the knife for blade play or edge deformation. But alas, nothing. So I stabbed the tip into the wood a few times and pried out some small chunks, and again, no change in the edge or tip. So I decided to chop the 2×4 in half. I realize this isn’t some impossible task, but with this blade shape, comfortable handle, and weight of the knife, it just felt easy.

Maybe about a minute on one side of the wood, flipped it over, and another minute on the other side, and it was chopped in half. I could feel very slight edge rolls, but no chipping, no blade play, and no change in the action of the knife. This is about as hard as I imagine anyone using their folder. Stabbing, twisting, prying and chopping is all in a day’s work with the AD15. I sharpened it up after this, with no issues, and had it back to a hair whittling edge in maybe half an hour.

Alternatives

There are technically 3 versions of the AD15. We have this particular model, made by Cold Steel, with either black or green scales available. The next closest alternative is the Demko AD15MG, which is the machine ground (hence the MG) variant made by Demko knives. This variant has some upgrades in certain areas of the knife, such as 20CV blade steel, titanium liners rather than steel, multiple handle scale choices, and a much higher level of polished fit and finish. This variant will put you back $675, so it may not be a true alternative to the Cold Steel, but it’s worth mentioning. Oh, and if you’d like to get the absolute best AD15 around, there’s the AD15HG, which is hand ground by Mr. Demko, which teeters right on the $1,000 mark. This higher end model comes with an optional secondary lock, too, for just about the most secure lock ever made for a folding knife.

The Cold Steel SR1 has been dubbed, by many heavy-hitting YouTube reviewers, as the toughest Cold Steel knife, or maybe even the toughest folder ever. And I’d say it’s quite comparable to the AD15 as an alternative. It is a bit less expensive, at $160 (vs the AD15’s $215 price tag), but has some similarities, too. They’re both built for “hard use” (which to me, means that they can be pushed into fixed blade roles), both designed by Andrew Demko, and they both use CPM-S35VN blade steel. The SR1 is a bit of a longer knife, with a 4” blade, while the AD15 sports the slightly shorter 3.6” blade. The SR1 is a little heavier, too, at 7.3 oz. The SR1 also uses the more commonly applied Tri-Ad lock; another Demko claim to fame. These knives really seem to scratch the itch of a fixed blade, but in a folding knife configuration.

The Cold Steel AD10 (which also has the Demko upgraded variants) is truly a brother from another mother to the AD15. The blade has a very similar profile, but uses the Tri Ad lock instead of the scorpion lock. The handles of these 2 behemoth brothers look very similar, weigh just about the same, and the designer’s style comes through in just looking at them side by side. The AD10 sports some contoured G10 handle scales, and originally was made with a hollow ground blade, but later changed to a flat ground, likely for a more robust edge geometry. It’s only slightly cheaper than the AD15, with a price of about $190, but comes out of the Taiwan Cold a Steel factory just like the AD15 and SR1.

Spyderco’s Shaman, designed by Sal Glesser himself, is my last entry into the comparison battle for the AD15. This is at the top of my personal list for Spyderco models that are in current production. The Shaman comes, in its base form, with contoured black smooth G10 handle scales, a 3.6” S30V blade, and has a price tag of just over $200. It has received Spyderco’s “sprint run” and dealer exclusive treatment many times over, so if you’re a collector looking for a knife with 10’s of variants, this is a knife to put on your list. It’s one of Spyderco’s hard use knives, and it’s utilizing the fidget-friendly compression lock, allowing the blade to be swung closed without putting any fingers in the blade path. We have a review on the Shaman as well, so if you’d like to take a more in-depth look at this model, go ahead and check out our time with it.

Conclusion

The Cold Steel AD15 is a very well executed production version of a custom knife, with a proprietary lock, and some abuse tolerance built in. It’s unique, well built, priced fairly, and loves to be used. It’s comfortable handle allows for some extensive cutting periods without too much discomfort, save for some slightly rough jimping and some aggressively rough G10. It’s not something you’d call an urban EDC champion, but in carrying it for a few weeks as my personal user, I didn’t have any problem with it. It’s heavy, it chews on pockets with repeated use, and isn’t as refined as it’s higher end custom variants.

But after carrying it and using it for a while, it all kind of feels normal, and it’s confidence inspiring lock and overall design give it that toughness you’d want for the outdoors situations, or for just opening up a package. If you can stomach a heavier knife, and want something a little different than just another back lock folder, this is a great option with little to complain about.

- Great hard user, priced well for its build, comfortable handle, well executed production variant of a custom.

- Exposed blade tang, quite heavy, aggressive jimping and G10, scorpion lock needs acclimation time.

Cold Steel AD15

Quality/Performance - 85%

Value for Money - 76%

81%

The Cold Steel AD15 is a well built heavy duty folder which is well worth your consideration.